‘OFAJ worked 24x7 to supply155 mm shells for Bofors gun’

| Date :23-Jul-2024 |

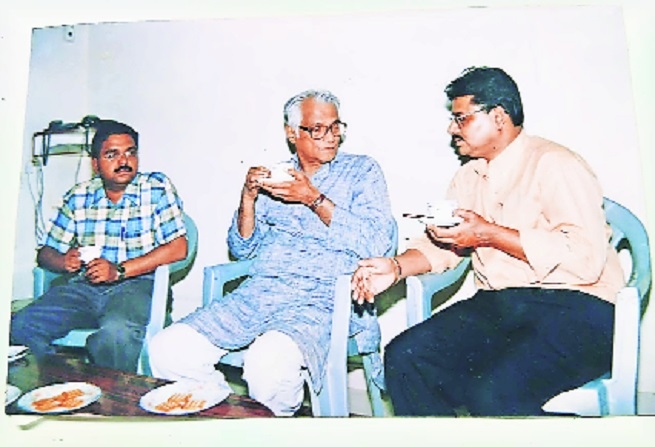

D Rajagopal (Centre), the then Chairman of Ordnance Factory Board, explaining to then Defence Minister George Fernandes the process of forging at Shell Forge section in OFAJ.

C P Agrawal, the then General Manager of OFAJ, also looks on.

By Kaushik Bhattacharya :

25 Years of Kargil Victory A Recall

- Ordnance Factory, Ambajhari (OFAJ) was the sole unit manufacturing 155 mm shells for the Bofors gun in the country

- Vinod Munghate, the then Dy GM (OFAJ), reminisces meeting then Defence Minister George Fernandes, during an impromptu visit to the OFAJ

- Munghate recalls how, even though interaction with VIPs was not allowed, Fernandes held a tete-a-tete with the workers, to motivate them and bolster production of the shells

The Bofors guns, which were used for the first time as direct fire role weapon in the Kargil war in 1999, inflicted huge casualties on the Pakistan forces and were instrumental in helping Indian soldiers regain territory and eventually, win

the war.

But, without the 155 mm ammunition, the Bofors was useless. And to gain an advantage and conquer this difficult battle on challenging terrain, the Indian Army felt the need of these guns with 155 mm shells which was sole handedly provided by Ordnance Factory Ambajhari (OFAJ), Nagpur during those days.

The war was in full swing at Kargil and Bofors gun was extensively used by the Army. In this situation, the Army felt the requirement of 155 mm shells as the shortage of ammunition surfaced before the Army.

The then Defence Minister George Fernandes interacting with Vinod Munghate and other staff of OFAJ during his visit.

The then Defence Minister George Fernandes realised that there was a need to motivate the workforce of Ordnance Factories to boost-up the supplies of ammunition including 155 mm shells which was the main feeding source to Bofors gun.

With this perspective,

Fernandes visited OFAJ, which was the only hardware manufacturer (shells and fuzes) of 155 mm Bofors guns in the country.

The Shell Forge and Shell Machine shops in OFAJ were the two big and important sections. These were responsible for manufacturing of these 155 mm shells.

Vinod Munghate, the then Deputy General Manager in OFAJ, who was looking after the Shell Forge shop during Kargil War recalls meeting Fernandes, known for his simplicity, wearing khadi kurta, pyjama and chappal visited factory and personally visited all the important shops in the factory and interacted with every workman and staff there.

“In each production shop, he mixed with the workmen and tried to give the message to workmen and staff that the war was on, there was need to increase production.

The mixing up with workmen was against the security norms of factory, as the workmen are not allowed to meet and talk to the VIPs on the shop floor. This was the aura of Fernandes that he immediately connected with the workmen being a past Union leader,” said Munghate.

Ignoring the unbearable working conditions of Shell Forge shop, Fernandes entered there and interacted with the workmen with great interest and intimacy.

He also addressed all Indian Ordnance Factory Services (IOFS) officers, Directorate General of Quality Assurance (DGQA) officers, Indian Air Force officers, representatives of the Works Committee, Joint Consulting Machinery (JCM) members and representatives of various unions and encouraged them to increase the production of 155 mm shells.

Munghate said, “Fernandes gave the message that our soldiers were fighting a war at Kargil and we had to ensure that adequate quantity of ammunition was supplied to the Army. We had to give a befitting reply to Pakistan’s misadventure at Kargil frontier. The prestige of the nation was at stake.

Therefore, he wanted OFAj to step-up supplies of ammunition hardware.”

“We were aware that OFAJ was going to play a key role in the war as we were the only producers of the 155 mm ammunition for Bofors guns. However, we never imagined that the Defence Minister himself would visit the factory and interact with the whole staff of OFAJ. Interaction with Fernandes was so encouraging that all unions came together and decided to support the management for increasing production of all required equipment of the Indian Army,” said Swapan Kumar Bhattacharya, the then Works Committee Member.

Munghate said, “After the meeting, all unions and Associations decided to extend full support and all workers, staff and officers were self motivated to increase the production.

The factory was working round-the-clock and the inspection wing of DGQA also extended full support.

“Immediately after start of Kargil war, we got orders from the Ordnance Factory Board (OFB) to scale up the production of 155 mm shells to cater to the demand of Army. Following the same, we started production to the fullest of our capacity,” said Munghate.

“The 4x4 version make Forging Press supplied by the USA on which the forging of 155 mm ammunition for Bofors gun took place, was running 24 hours without a break. Similarly, the machining of shells on Computer Numerical Control (CNC) machines was done to full capacity. During that period, we supplied around 10,000 shells of Bofors guns per month to the Indian Army. Whereas, the forging production was stepped up to 1,000 shells per day during that period,” said Munghate.

He also mentioned that after the war, OFAJ decided to increase the production capacity of 155 mm shells upto 80,000 per year and with the dawn of modernisation of industrial machines, we scaled up the target upto 1,00,000 shells per year.

“Such was the spirit of nationalism, that no one raised the question regarding the extended working hours. The only objective before them, was to deliver maximum shells of 155 mm ammunition to the filling factory, Ordnance Factory Chandrapur (OFC), for explosive filling, assembly and final dispatch to the Indian Army,” he added.

For the supply of 155 mm shells, OFAJ and OFC were the only factories in India producing shells and fuzes and explosive filling and assembly respectively.

Equally important was the contribution of Ordnance Factory Itarsi and Cordite Factory, Arvankadu, for developing explosives for propellant charge 8 and 9 respectively for firing 155 mm ammunition from the Bofors gun.

The noteworthy point was that the three variants of the 155 mm ammunition of Bofors design -- M107, 77B, and HEER produced by the OFAJ and OFC proved to be a lethal combination, the ammunition and the dependable Bofors gun.

In those days, the shells were made on the basis of a transfer of technology (TOT) received from Sweden. However, the Ordnance Factory Ambajhari team came up with an indigenous version with a much higher range, claimed Vinod Munghate.